KGA261 Rebeamer/ Long Chain Beamer

Category:

Divide again the colored bunched yarns into single-piece parallel warp slices and evenly wind up to colored warp beam for use by warp beam starching and other workmanships.

Keywords:Super-High-Speed Direct Warping Machine,Smart-high-Speed Sectional Warping Machine

Inquiry

Scope of Application

Divide again the colored bunched yarns into single-piece parallel warp slices and evenly wind up to colored warp beam for use by warp beam starching and other workmanships.

Technical Features

1. Apply the mode of first grade motor belt transmitting warp beam and frequency control to realize stepless setting of line speed and maintain constant line speed during the warping process.1.jpg

1. Apply the mode of first grade motor belt transmitting warp beam and frequency control to realize stepless setting of line speed and maintain constant line speed during the warping process.1.jpg

2. The winding tension of yarn rolls can be regulated and set according to the process requirements. By applying frequency transmission of tension bracket and through information feedback of tension of backwind swaying bracket, the yarns can be compensated for tension in real time, which can realize the density control of warp beam yarn rolls and guarantee the density consistency of rolls among all warp beams. The tension roller of tension bracket uses crossing mode for successful backing-off of yarns.

3. The new type of yarn storage device can back wind the yarns on the warp beam into the yarn tube to reduce the breaking probability when backing machine, realize tension control of backed rolled partial yarns when warping again and improve the quality of yarn-diving warp beam.

3. The new type of yarn storage device can back wind the yarns on the warp beam into the yarn tube to reduce the breaking probability when backing machine, realize tension control of backed rolled partial yarns when warping again and improve the quality of yarn-diving warp beam.

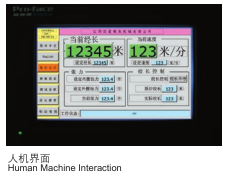

4. Measure the warping length and speed by various kinds of sensors, having functions of automatic length and speed measuring, fixed length control, fixed length and automatic stopping of lease wires.2.jpg

5. Apply warp beam hydraulic clamping mode of braking. Yarn guiding roller and tension roller air braking, characterized in stable braking and simple and reliable operation.

6. Apply air-operated warp beam lifting and power-driven switching warp beam with simple and convenient operation.

7. Reciprocating yarn prodding device and vibrator on the tension bracket can successfully separate the yarn during the proceeding process to guarantee successful yarn dividing and increase warping speed to prevent yarn winding.

8. On the host machine, there is installed with applicable devices of safety rail protecting device,support for flying protecting fan and lighting lamp supports etc.

9. The computer contact screen is characterized in convenient and visual operation and big display information.

10. The back-winding workbench of yarn storage tube can be configured according to the users' requirements.

Main specifications

1. Fabric width of warping beam:1600、1800mm

(Other fabric width could be customize according to the requirement of customer)

2. Max. diameter of warp beam:800mm、1000mm

3. Speed of beam warping:≤500m/min

4. Power of beam warping motor:15KW

5. Power of yarn tailing motor:0.12KW

6. Power of blasting motor:0.18KW×2

7. Braking length:≤2M (300m/min)

18. Left and right adjustable range of reed:0-40mm

9. Max. tension:500N

0. Operation displayer:10.4 inch touch panel

11. Overall dimensions:1600mm:3600mm(length)×1850mm(width)×2250mm(height)

1800mm:3800mm(length)×1850mm(width)×2250mm(height)

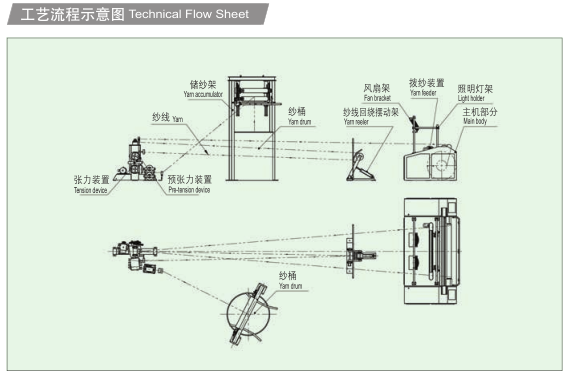

Technological Flow Diagram

Contact Us

More Products

Contact us to learn more about our business solutions

Fill out the form below to receive news and industry insights about emerging products that are sent directly to your inbox