KGA339 Warping-Sizing Combinatorial Machine

Category:

In textile industry, KGA339 type warping-sizing combination machine is the facility for preparation before spinning. It can meet the craftwork standard in sizing wool,cotton, hemp, mixed fabric and gr

Keywords:Super-High-Speed Direct Warping Machine,Smart-high-Speed Sectional Warping Machine

Inquiry

Scope of Application

In textile industry, KGA339 type warping-sizing combination machine is the facility for preparation before spinning. It can meet the craftwork standard in sizing wool,cotton, hemp, mixed fabric and grey fabric. It has both advantages of sectional warping machine and sizing machine, which makes warping and sizing completed once, and directly ccomplish the production of beam. KGA339 is suitable for small quality production, multiplicity production and sample production. It is also suitable for the sizing and warping process in new products research.It has advantages of low percentage of yarn coverage,good integrity of chorion, quick replacement of the older generation products by new ones, high efficiency, good quality, saving raw materials as well as supplemental materials, reducing production cost.

KGA339 is suitable to size and warp yarns used in color-woven fabric, wool fabric, silk fabric or special industry fabric, despite of the count and density.Controlled by computer,and structured reasonably, the new technology machine is stable and reliable, and can match with rapier, projectile, air-jet looms, etc.It is a good choice for substituting the imports.

Technical Features

1. Controlled by microcomputer, touch man-machine interface, advanced technology, convenient operation and friendly interface;

2. Mechanical, electronic, gaseous, liquid integration, advanced technology, stable property, reliable running;

3. Advanced AC servo, high precision, quick response, little deviation

4. Powerful function microcomputer system and advanced control method enables the system running steadily, reliably and having high degree of intelligence;

5. Advanced AC vector synchronous controlling system,with high precision,quick response and low overshoot;

6. During warping course, constantly data sampling, analysis, calculation to keep the system in best condition, make neat yarn figuration, well-distributed density, good quality, stable and well-distributed beaming tension;

7. Dual-dipping and dual-pressing mode is applied to slurry tank.

8. Pneumatic pressurizing and 2nd roller linear pressurizing ensures uniform starching.

9. Self-controllable tank temperature. Double interlayer of the tank ensures good insulation.

10. Integral main and assistant tank and countercurrent circulation ensures stable slurry viscosity.

11. Bake materials with full-enclosed drum. It features independent temperature control of two sections, high efficiency and good adaptability.

12. Active driving used on pump in drying cabinet makes wet area extension more easily.

13. Applies air-hydraulic supercharging caliper brake with high efficiency of braking.

Main specifications

1. Application scope: 6s - 100s pure cotton yarn, terylene cotton yarn, flax

2. Work width: 1800-32000 (according to customer request)

3. Cone angle: 1:8

4. Flange diameter:<1000 (mm)

5. Steam capability: 180kg/Hr (vapor pressure ≤ 0.35 Mpa)

6. Warping speed: 2-100 (meter/minute)

7. Displacement range: 0.001-9.999 (mm)

8. Beaming speed: 0-100 (meter/minute)

9. Tension of beaming:<6000 (N)

10. Stock rough volume: main stock rough 56(L)

11. Precision of displacement: 0.001 (mm)

12. Assistant stock rough: 51 (L)

13. Paired bar precision: 0.01 (mm)

14. Installed power: about 40kW

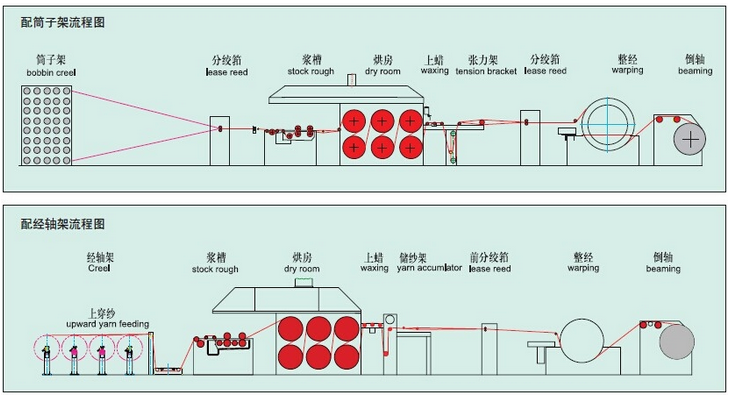

Technological Flow Diagram

Contact Us

More Products

Contact us to learn more about our business solutions

Fill out the form below to receive news and industry insights about emerging products that are sent directly to your inbox